Waste Plastic Product Machine

Our Waste Plastic Product Machine tackles India’s plastic pollution crisis directly. This advanced plastic recycling machine uses Thermomesh technology. It efficiently processes thin plastic waste, specifically materials under 150 microns. Importantly, our machine transforms discarded plastic into useful eco-bricks and paver blocks.

This plastic product machine offers scalable solutions for municipalities and industries across India. It helps achieve waste management compliance. Furthermore, the machine enables efficient waste-to-wealth conversion. This directly supports Swachh Bharat Abhiyan goals and circular economy principles. Overall, this innovation makes sustainable infrastructure achievable throughout India.”

Pioneering the Plastic Waste Control Project: A Municipal Model

“The Municipal Corporation’s Clean City Model is setting a new standard. Indeed, it serves as a powerful role model for other cities in India. Our Plastic Waste Control Project (PWCP) actively reduces plastic pollution in urban areas.”

“This innovative project directly involves residents. For example, people receive ten rupees per kilogram for properly disposing of their plastic waste. Ghantagadi vehicles play a crucial role here. They facilitate efficient plastic collection and reward residents with valuable tokens. This system encourages wider participation in waste management.”

“Once collected, the plastic waste transforms into useful products. We use plastic bricks to create essential public infrastructure. For instance, these eco-friendly bricks build durable road dividers, paver blocks, and footpaths. Furthermore, the project addresses non-plastic waste efficiently. This organic waste is then converted into valuable biodegradable fertilizer.”

“This exemplary waste management model encourages nationwide adoption. It offers a practical path towards a much cleaner environment across India. Ultimately, it champions sustainable practices for all communities.”

Why India Needs Our Waste Plastic Product Machine (WPPM)

“Plastic waste disposal presents a critical challenge worldwide. India alone generates over 26,000 tons of plastic waste every single day. Shockingly, news reports indicate that 40% of this waste remains untreated. This untreated plastic significantly contributes to air, water, and land pollution. This urgent problem clearly shows the need for innovative plastic recycling solutions. We must transform plastic into reusable, sustainable forms.”

“Our revolutionary Waste Plastic Product Machine (WPPM) offers a groundbreaking solution to this environmental crisis. Mr. Chanakya Bhaskar invented this technology. This patented Thermomesh technology efficiently recycles plastic waste. Furthermore, it creates versatile products like plastic bricks, paver blocks, and road dividers. These eco-friendly products have many uses in public infrastructure projects. For example, you can use them for footpaths and security walls. This machine truly delivers a sustainable and scalable approach to plastic waste management.”

Key Features of Our Waste Plastic Product Machines (WPPM)

“Our Waste Plastic Product Machines (WPPM) offer many important advantages. Firstly, waste plastic is abundantly available as a raw material. This provides a unique chance to change environmental management using new recycling technologies.”

“Secondly, our DR Products, like plastic blocks, have a remarkably long lifespan. They last much longer than traditional materials. Consequently, they greatly reduce waste build-up. Furthermore, plastic bricks from our WPPM show excellent insulation properties. This makes them perfect for building walls in India’s diverse climates. Consider their use from the cold of Jammu and Kashmir to the heat of Rajasthan.”

“Moreover, these plastic-based products offer superior strength. They have a compressive strength of 24 N/mm². This is much stronger than conventional materials, which are rated at just 3 N/mm². Additionally, their high softening point of 150°C ensures durability, even in challenging environments.”

“Lastly, once waste plastic is molded into specific shapes, it becomes permanently fixed. This means it eliminates the need for frequent recycling. Therefore, it strongly supports a truly sustainable production model.”

“Overall, this advanced waste plastic technology provides a powerful solution to the global plastic waste crisis. It actively drives sustainable practices within the construction and waste management sectors across the world, including India.”

WPPM Technology: A Invention by Chanakya Bhaskar

“The Waste Plastic Product Machine (WPPM) is a groundbreaking invention by Deshmukh Research Industry. This plastic recycling machine offers a truly sustainable solution for waste management. Mr. Chanakya Bhaskar, the inventor of PWCP, developed this key technology. Importantly, it uses patented Thermomesh technology.”

“This powerful WPPM transforms various types of plastic waste. It handles municipal, road, and industrial plastic efficiently. The machine converts this waste into durable, eco-friendly products. For example, it creates strong plastic bricks, paver blocks, and road dividers. This plastic product machine suits various needs. It works well for small apartment recycling and also for large municipal operations.”

“The WPPM operates using its unique Thermomesh Technology. This process converts plastic waste into a semi-liquid state. We use controlled heat, crucially without combustion. This method preserves the plastic’s core properties. Furthermore, this process greatly minimizes pollution. It also ensures very high-strength outputs. For instance, WPPM products have a compressive strength exceeding 24 N/mm².”

“Our Waste Plastic Product Machine is highly energy-efficient. It specifically processes plastic waste that is below 150 microns. The machine features a compact design and is easy to operate. Additionally, it includes advanced safety features. These qualities make it ideal for urban, rural, and industrial uses across India.”

“Beyond reducing landfill overflow, the WPPM actively contributes to a circular economy. It creates valuable infrastructure products from waste. This process permanently sequesters waste plastic, locking it into useful forms. As a leader in innovative recycling technologies, Deshmukh Research Industry is driving global efforts. We aim for sustainable development and environmental preservation.”

“Mr. Chanakya Bhaskar leads a visionary initiative: the ‘Plastic Waste Control Project (PWCP)’. This project uses our cutting-edge ‘Waste Plastic Product Machine’ technology. Its main goal is to tackle the huge plastic pollution problem in India and worldwide.”

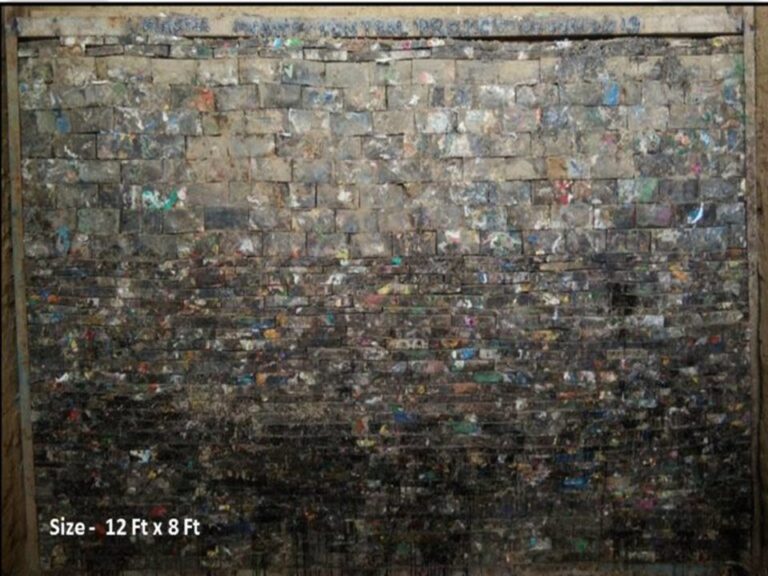

“This project utilizes patented technology. Currently, a municipal corporation processes approximately 1.2 tons of waste plastic. This yields 800 plastic bricks. These bricks then help create something truly remarkable: the world’s first plastic wall! This unique wall, built entirely from waste plastic bricks, stands proudly in Jammu and Kashmir.”

“This remarkable plastic wall offers an innovative solution. It provides excellent insulation, even in zero-degree areas. Thus, it offers comfortable living accommodations. Several respected VIPs actively support this project. These include Karan Dhawan, Madhavji Kulkarni, Sameer Joshi, Satish, and Ganesh Mali. They passionately contribute to safeguarding our environment from plastic pollution.”

“The Plastic Waste Control Project offers dual benefits. Firstly, it converts waste plastic into useful, durable forms. Secondly, it effectively helps mitigate cold temperatures in insulated structures. Therefore, this project represents a significant step towards both sustainability and environmental preservation.”

Chanakya Bhaskar’s Revolutionary Solution: The Waste Plastic Product Machine (WPPM)

Chanakya Bhaskar, a visionary in environmental technology, introduces an inventive Waste Plastic Product Machine (WPPM). This is a pivotal development in the fight against plastic pollution. This cutting-edge invention directly converts waste plastic into functional products. These include plastic bricks, paver blocks, and road dividers, all without needing segregation.”

“The WPPM uses advanced patented technology. This ensures an efficient, eco-friendly, and scalable solution for managing plastic waste. Furthermore, it uses ‘Thermomesh Technology’. This technology processes plastics into a unique semi-liquid state. This enables the creation of durable and versatile products.”

Thermomesh Technology: Revolutionizing Plastic Recycling

Thermomesh Technology is a patented innovation. Chanakya Bhaskar developed this key technology. It forms a cornerstone of our

Waste Plastic Product Machine (WPPM). This advanced process uses precise thermal regulation. It transforms plastic waste into a unique semi-liquid state. Crucially, this happens without any combustion. This method preserves the structural integrity of plastic polymers.”

“Thermomesh Technology efficiently molds plastic into robust and versatile DR products. These include plastic bricks, paver blocks, and road dividers. The technology is designed for eco-friendly operations. It optimizes the plastic recycling process by adapting to the availability of waste plastic. This ensures seamless compatibility with the WPPM machine.”

“Ultimately, Thermomesh Technology stands as a transformative solution. It actively addresses plastic pollution. Furthermore, it advances sustainable infrastructure development across India and globally.”