WASTE PLASTIC PRODUCT MACHINE

Waste Plastic Product Machine

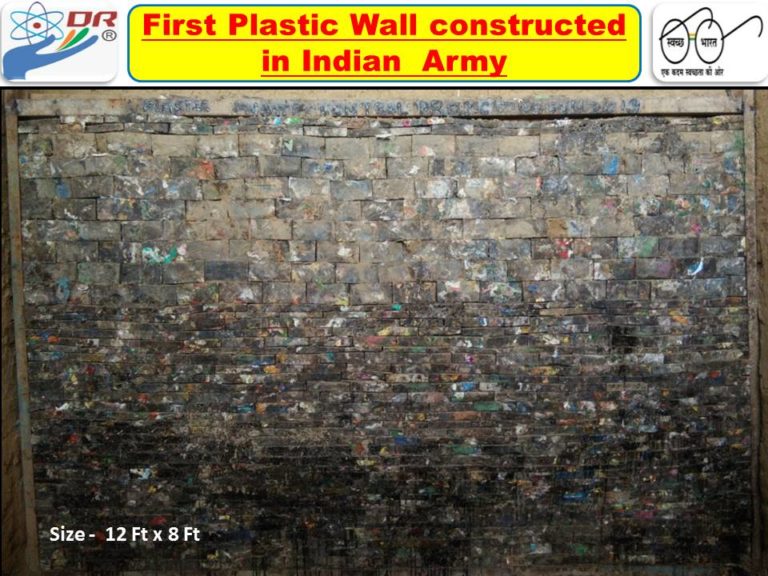

The Municipal Council has achieved remarkable success with its Waste Plastic Product Machine plant, offering an exemplary model to the world. This cutting-edge facility can efficiently process all types of waste plastic under 100 microns, transforming them into useful products such as plastic bricks and paver blocks. Notably, these bricks were recently employed in the construction of plastic walls in the Jammu and Kashmir region, showcasing their potential for social purposes.

A Pioneering Approach: Municipal Corpo. Plastic Waste Control Project Sets the Standard

1. Municipal Corpo. Clean City Model serves as a role model for other cities.

2.Plastic Waste Control Project reduces plastic pollution.

3.Residents receive ten rupees per kg for disposing of plastic waste.

4.Ghantagadi facilitates efficient plastic collection and rewards with tokens.

5.Plastic bricks used for road dividers, paver blocks, and footpaths.

6.Non-plastic waste used as biodegradable fertilizer.

This exemplary model encourages nationwide adoption for a cleaner environment.

NEED OF WPPM TECHNOLOGY

1. Disposal of waste plastic is a pressing global challenge, with India alone generating a staggering 26,000 tons of waste plastic daily. The National Pollution Control Board reveals that 40% of this waste remains unmanageable, leading to pervasive pollution of air, water, and land. To address this critical issue, the need for recycling plastic and transforming it into reusable forms becomes paramount.

2. In a groundbreaking effort, Mr. Chanakya Bhaskar has invented the revolutionary “Waste Plastic Product Machine” technology. This innovative solution recycles plastic waste, converting it into highly versatile products like bricks that find applications in footpaths, security walls, and more. This promising development presents a sustainable approach to tackle plastic waste and create valuable resources for civil necessities.

Salient Features of WPPM Machines

1.The easy availability of waste plastic as a raw material provides a pivotal opportunity for a groundbreaking environmental solution.

2.Plastic blocks exhibit a significantly longer lifespan compared to conventional products, enhancing their sustainability and reducing waste accumulation.

3.Plastic bricks, when used to construct walls, serve as exceptional insulation partitions, capable of regulating temperatures in both cold and warm regions like Jammu and Kashmir and Rajasthan.

4.With an impressive strength of 24 N/mm², plastic products surpass the resilience of normal products rated at 3 N/mm². Moreover, their softening point of 150 degrees Celsius ensures durability under various conditions.

5.Waste plastic, once molded into a particular product shape, remains permanently fixed, eliminating the need for frequent recycling, reducing, and reusing processes.

This innovative waste plastic product technology holds significant promise in combatting the global plastic waste crisis and promoting sustainable practices worldwide.

Details of Waste Plastic Product Machine Technology , Which Invented by Chanakya Bhaskar, Inventor PWCP.

Plastic pollution has escalated into a significant global concern, with India alone generating a staggering 25,490 tons of plastic daily. Shockingly, the Central Pollution Control Board’s report indicates that 40% of this waste, amounting to 10,340 tons, remains unmanaged. In large cities alone, 6,137 tons of plastic are left unutilized, exacerbating the plastic problem.

However, there is hope on the horizon with inventor Chanakya Bhaskar’s ingenious creation, the Waste Plastic Product Machine. This revolutionary device can directly process any type of plastic found in garbage depots into valuable products like plastic bricks, paver blocks, and tree guards.

To address the plastic waste crisis effectively, Mr. Chanakya Bhaskar proposes integrating his “Plastic Waste Control Project” into nationwide campaigns like Swachh Bharat Abhiyan and Rural Development initiatives. By incentivizing plastic collection with a ten-rupee per kg rate, this project could potentially generate over 5,000 crore rupees worth of jobs annually for disadvantaged communities.

The realization of this vision in your municipal city could serve as a role model, showcasing the immense potential of this innovative solution to combat plastic pollution and uplift marginalized sections of society.

Mr. Chanakya Bhaskar’s visionary “Plastic Waste Control Project (PWCP)” utilizing the cutting-edge “Waste Plastic Product Machine” technology aims to tackle India’s and the world’s plastic pollution problem. With a patented technology, the municipal corporation is currently processing approximately 1.2 tons of waste plastic to produce 800 bricks, leading to the creation of the world’s first plastic wall constructed entirely from waste plastic bricks in Jammu and Kashmir.

This remarkable plastic wall serves as an innovative solution, providing insulation in zero-degree areas and offering comfortable living accommodations. VIPs like Karan Dhawan, Madhavji Kulkarni, Sameer Joshi, Satish, and Ganesh Mali are passionately involved in this project, contributing their support to safeguard the environment from plastic pollution. The project’s dual benefits lie in converting waste plastic into usable forms while effectively mitigating cold temperatures, making it a significant step towards sustainability and environmental preservation.

*** Chanakya Bhaskar’s Initiative Paves the Way for a Responsible Clean India Campaign ***

1.The innovative Plastic Waste Control Project in Islampur sets an exemplary model for the entire area, rewarding citizens with ten rupees per kilogram of plastic to incentivize responsible plastic disposal. This approach can be replicated in any city with a population under 50,000, effectively curbing plastic littering as people now see value in plastic waste.

2.The introduction of the Ghantagadi, a specialized garbage collector vehicle, facilitates plastic collection. Individuals receive tokens equivalent to the weight of their deposited plastic, which can be redeemed for cash at the municipal corporation. Limiting the collection to five kilos per person per day ensures fair distribution.

3.The plastic bricks produced through this initiative find practical applications in road dividers, paver blocks, and footpaths within municipal gardens, contributing to sustainable infrastructure development.

4.The separation of non-plastic waste allows for the generation of biodegradable fertilizer, which can be sold at four rupees per kilogram.

5.This successful role model can be replicated nationwide, fostering a cultural shift towards cleanliness and paving the way for a cleaner India, with an estimated 70% improvement in overall cleanliness.

Golden theory of waste plastic material

Machine small in size or large size does’t matter, also how many creating heat doesn’t matter. But waste plastic must be take a required heat and it convert its original solid stage in to liquid stage but not become liquid. It stage in between solid and liquid stage. In this period can be given required shape to waste plastic and properties of created products use in our normal life. This theory called golden theory of waste plastic material.